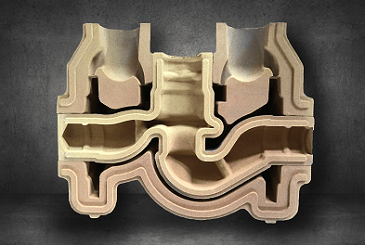

Norton Commando 850 Cylinder Barrels now cast by NovaCast

One of several OEM Norton Motorcycle components being manufactured by NovaCast. These Norton Commando 850 cylinder barrels are cast in BS1452 Grade 17 cast iron using the shell mould casting process then powder coated, machined and honed to original specifications. We are also producing complex wheel hubs with cast-in inserts and various other components for...

Casting Process Comparison: Sand Casting vs Shell Mould Casting

In this article we consider the differences and similarities between two closely related casting processes. Both use sand moulds to produce castings but the differences in the processes make them suited to quite different applications. Sand casting is one of the oldest casting processes dating back at least 5000 years. The simplicity and versatility of...

New Casting Process Data Sheets

Following the recent re-launch of our website, we have continued to add new content and I wanted to point you in the direction of our data sheets. We now have over 30 on the site covering the technical specifications of all the main alloys that we cast. We have also recently added data sheets for...

Choosing the right metal casting process

Selecting the right casting process for making a metal component is an important consideration at the early stages of product design. NovaCast has produced a guide that aims to highlight the considerations, and emphasise the importance of working closely with your foundry's design engineering team.

What is Shell Mould Casting?

At NovaCast, we offer a wide range of casting process options as each have strengths and weaknesses that make them suited to certain applications and alloy choices. Shell Mould Casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable sand-based mould. However, in Shell Mould Casting,...