Casting Process Comparison: Sand Casting vs Shell Mould Casting

In this article we consider the differences and similarities between two closely related casting processes. Both use sand moulds to produce castings but the differences in the processes make them suited to quite different applications. Sand casting is one of the oldest casting processes dating back at least 5000 years. The simplicity and versatility of...

NovaCast adds to its sand core production facilities

Small but perfectly formed. Our new resin-sand mixing machine will improve both flexibility and efficiency at our Melksham foundry. The 1-Tonne per hour capacity may be small but it is the perfect solution for sand-core and small mould production, complementing the existing larger scale equipment on site.

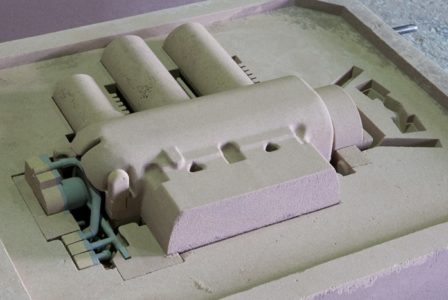

How cores extend the flexibility of sand casting

Creating cores is an art in itself and follows many of the principles that dictate the production of sand moulds. Without cores, the use of sand casting would be far more limited. In addition to the ability to introduce more complex designs, internal voids and structures, cores can deliver other benefits. Even where internal voids are not needed...

The Difference Between Gravity and Pressure Die Casting

Die casting is one of the most widely used casting processes but what is the difference between Gravity Die Casting and Pressure Die Casting? Both are casting processes used by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Both forms of Die Casting employ a metal mould into...

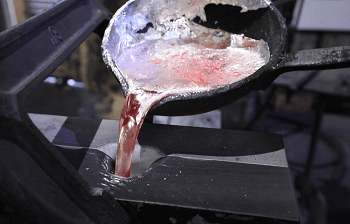

Elements of a Sand Casting Running System

The gating system includes all those elements which connect the pouring ladle to the mould. The various elements include: Pouring Basin or cup, Sprue, Sprue Base Well, Runner, Runner Extension, In-gate and Riser. An effective gating system should: Fill the mould cavity completely before the metal starts to solidify Control the speed that metal enters...

The case for Sand Casting

The Sand Casting process has been a key element in manufacturing for thousands of years and still accounts for approximately 70% of all castings. Whether Sand Casting is the best option for the production of a particular component will be dictated by considerations such as the required geometry, performance, alloy choice, production run, tolerance within...