Elements of a Sand Casting Running System

The gating system includes all those elements which connect the pouring ladle to the mould. The various elements include: Pouring Basin or cup, Sprue, Sprue Base Well, Runner, Runner Extension, In-gate and Riser. An effective gating system should: Fill the mould cavity completely before the metal starts to solidify Control the speed that metal enters...

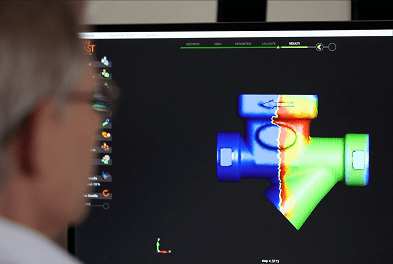

Casting Process Simulation Complements Traditional Foundry Expertise

Casting Process Simulation is used by NovaCast to develop comprehensive modelling of the intended production process to determine the size and shape of sprues, runners, gates, and risers. One of the main benefits of these systems is that they make it possible for us to quickly identify areas within the casting geometry that could give...

Casting Design Considerations for Design Engineers

The design and manufacture of a metal component involves a multitude of decision points and will be influenced by considerations such as structural performance, weight, lead time, cost and aesthetics. It is understandable, therefore, that thoughts about how precisely that component is going to be manufactured are often left until the design is at a fairly...

Sand Casting Foundry: Where tradition meets technology

Sand casting is a traditional process dating back many thousands of years, but components produced using this process are still an essential part of our lives today. In this article we outline the sand casting process as carried out in a modern sand casting foundry, where technology and tradition are combined. Although it dates back...