Converting fabricated wheels to castings frees up welding capacity

Supply Plus Limited designs, manufactures and distributes a range of high quality, professional safety and fuel delivery equipment, including a mobile hose reel that has the capacity to hold up to 200m of 70mm lay flat hose. The design incorporates two wheels that were formally fabricated in-house. Due to the success of the hose reel...

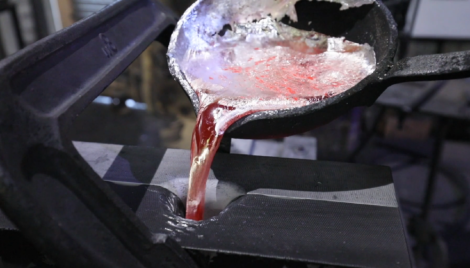

The rise and rise of aluminium as a casting material

Aluminium is one of the most important raw materials used in metal casting due, in part, to its combination of versatility, relatively low weight, and high strength. It is used in castings across a wide range of industries from aerospace to automotive and electronics to renewable energy. At NovaCast aluminium is one of the primary...

New Casting Process Data Sheets

Following the recent re-launch of our website, we have continued to add new content and I wanted to point you in the direction of our data sheets. We now have over 30 on the site covering the technical specifications of all the main alloys that we cast. We have also recently added data sheets for...

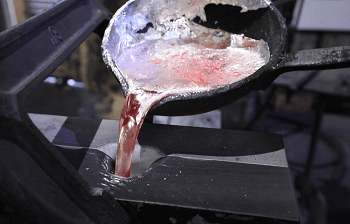

The Difference Between Gravity, Low and High Pressure Die Casting

Die casting is one of the most widely used casting processes but there are significant differences between Gravity Die Casting (GDC), Low Pressure Die Casting (LPDC), and High Pressure Die Casting (HPDC). Each are casting processes offered by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Getting metal...

Choosing the right metal casting process

Selecting the right casting process for making a metal component is an important consideration at the early stages of product design. NovaCast has produced a guide that aims to highlight the considerations, and emphasise the importance of working closely with your foundry's design engineering team.

The Difference Between Gravity and Pressure Die Casting

Die casting is one of the most widely used casting processes but what is the difference between Gravity Die Casting and Pressure Die Casting? Both are casting processes used by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Both forms of Die Casting employ a metal mould into...

The Importance of Parting Line Design in Gravity Die Cast Components

As part of our series of articles discussing various aspects of Gravity Die Casting, we are taking a look at the importance of parting line design. The parting line is where two or more sections of the Die split to release the casting. When deciding where to place the parting line, designers will need to...

The case for Gravity Die Casting

There are many different casting processes and each has its place. The inherent characteristics of each make them ideal for a particular component geometry, performance requirement, alloy choice, production run or tolerance within specification. Gravity die or permanent mould castings use a Cast Iron or Steel mould consisting of at least two parts. The most...

Top 10 Design Tips for Problem Free Gravity Die Casting

Gravity Die Casting (also known as Permanent Mould Casting) is a repeatable process primarily used to produce medium-run, dimensionally accurate, non-ferrous castings, most often in alloys of Aluminium, Zinc and Bronze. Here are the Top 10 Tips for designing problem-free casting geometry…