The Casting Design Development Process

In this article we run through a typical casting design process to highlight the importance of co-operation at an early stage between designer and foundry. A typical experience based on an iterative design process might be as follows. The role of the design engineers The product design engineer will design casting geometry based on the...

A NovaCast Guide: “Casting Design Considerations for Design Engineers”

While there is no substitute for a close working relationship at an early stage between the design engineer and their chosen foundry, we hope that this guide will be of assistance to product design engineers. It will give an indication of the often-conflicting factors that the production team within the foundry will need to take...

Choosing the right metal casting process

Selecting the right casting process for making a metal component is an important consideration at the early stages of product design. NovaCast has produced a guide that aims to highlight the considerations, and emphasise the importance of working closely with your foundry's design engineering team.

NovaCast invests in its reverse engineering capability with EinScan HX

The ability to accurately reverse engineer existing castings is essential to any modern foundry. Reverse engineering could be required for a variety of reasons ranging from replication of an old casting where original patterns have been lost to improving mechanical performance or learning from an existing design to replicate or improve it. Whatever the reason,...

A global response to a global pandemic

The global pandemic has presented manufacturing and logistical issues for companies all over the world. For NovaCast, the challenge has been to maintain the supply of componentsto critical industries at a time when its own supply chains have been under pressure. Every part of our supply chain had to perform to support an Australian manufacturer...

NovaCast: A single-source solution for both ferrous and non-ferrous castings

As any Design Engineer involved in the design for cast metal components will know, the selection of the metal alloy and casting process they will specify can be a complex process. Ultimately, for the Design Engineer, the specification must take account of parameters such as weight, yield strength, toughness, ductility, weldability, elasticity, shear, and thermal...

Rapid Prototyping: How 3D Printing is making its presence felt in the foundry

As a long-established foundry with its roots in sand and gravity die casting, NovaCast has grown and evolved over the years to become a modern, diverse and international foundry, with customers and production partners around the world. As the business has developed, it has embraced new casting processes, such as investment casting, lost foam casting,...

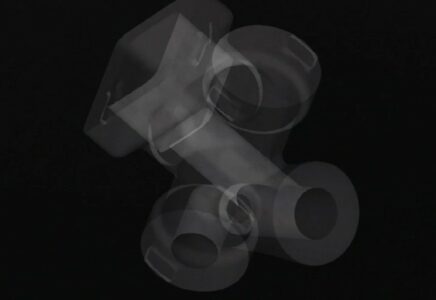

Types of shrinkage inherent in the casting process

We often say that casting molten metal is like handling a living thing. Understanding how different alloys will react to different casting processes, component geometry, running systems, temperatures, etc. is part of the art of the foundry engineer. In recent years, the wealth of experience built up at the NovaCast Foundry has been enhanced by...

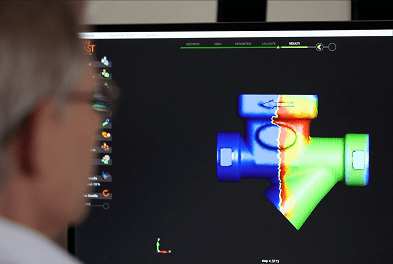

Casting Process Simulation Complements Traditional Foundry Expertise

Casting Process Simulation is used by NovaCast to develop comprehensive modelling of the intended production process to determine the size and shape of sprues, runners, gates, and risers. One of the main benefits of these systems is that they make it possible for us to quickly identify areas within the casting geometry that could give...

The Importance of Parting Line Design in Gravity Die Cast Components

As part of our series of articles discussing various aspects of Gravity Die Casting, we are taking a look at the importance of parting line design. The parting line is where two or more sections of the Die split to release the casting. When deciding where to place the parting line, designers will need to...

Casting Design Considerations for Design Engineers

The design and manufacture of a metal component involves a multitude of decision points and will be influenced by considerations such as structural performance, weight, lead time, cost and aesthetics. It is understandable, therefore, that thoughts about how precisely that component is going to be manufactured are often left until the design is at a fairly...

Top 10 Design Tips for Problem Free Gravity Die Casting

Gravity Die Casting (also known as Permanent Mould Casting) is a repeatable process primarily used to produce medium-run, dimensionally accurate, non-ferrous castings, most often in alloys of Aluminium, Zinc and Bronze. Here are the Top 10 Tips for designing problem-free casting geometry…

Top 10 Tips for switching fabrications and assemblies to castings

There are many reasons why a manufacturer may choose to substitute complex fabrications, weldments and assemblies for castings. Here are the top 10 tips for selecting suitable candidates for conversion.