Bringing a piece of British motoring heritage back to life

In the early 1900’s, British car manufacturers were at the forefront of motor vehicle development. The Vulcan Motor company, based in Southport, England, was one such innovator that produced cars from 1902 until the late 1920s. Today, early examples of Vulcan cars are extremely rare collectors’ items. NovaCast was approached by a specialist engineering company...

The Casting Design Development Process

In this article we run through a typical casting design process to highlight the importance of co-operation at an early stage between designer and foundry. A typical experience based on an iterative design process might be as follows. The role of the design engineers The product design engineer will design casting geometry based on the...

NovaCast: Facing the challenges of a sustainable future

When Richard Phillips took over as owner and Managing Director of NovaCast Limited, based in Melksham, UK, he did so with a commitment that the business would move towards a sustainable future. Richard felt that as both owner and Managing Director, he had a responsibility to consider the company’s impact on the environment and to...

Rapid Prototyping: How 3D Printing is making its presence felt in the foundry

As a long-established foundry with its roots in sand and gravity die casting, NovaCast has grown and evolved over the years to become a modern, diverse and international foundry, with customers and production partners around the world. As the business has developed, it has embraced new casting processes, such as investment casting, lost foam casting,...

NovaCast shows the way to a greener, more sustainable industry

Over the years the metal casting industry has acquired a reputation as one of the worst in terms of environmental impact, largely due to traditional production practices with high energy usage going in and highly toxic emissions coming out. Add to this the massive energy demands for the extraction and production of raw metals, such...

Casting Process Simulation Complements Traditional Foundry Expertise

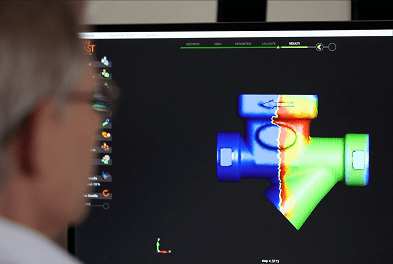

Casting Process Simulation is used by NovaCast to develop comprehensive modelling of the intended production process to determine the size and shape of sprues, runners, gates, and risers. One of the main benefits of these systems is that they make it possible for us to quickly identify areas within the casting geometry that could give...

Fabrication to Casting: Steam Trap re-design creates market leading solution

As specialists in the conversion of fabrications and assemblies to single cast components, NovaCast is cutting costs and improving efficiency for its customers. One such customer is EBE Engineering; manufacturers of an innovative Venturi Orifice Steam Trap. Originally a fabrication comprising a cast stainless steel body with two welded flanges; the steam trap was slow...

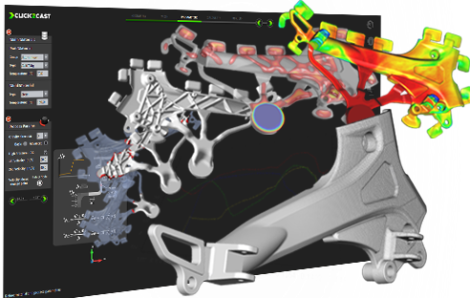

NovaCast invests in casting process simulation software

Following on from the acquisition of new 3D modelling software, and as part of our programme of continual improvement, NovaCast is investing in Click2Cast casting simulation software. The innovative and intuitive user interface will allow our engineers to identify potential casting issues, such as air entrapment, porosity and cold shuts, thanks to a simple and...

Sand Casting Foundry: Where tradition meets technology

Sand casting is a traditional process dating back many thousands of years, but components produced using this process are still an essential part of our lives today. In this article we outline the sand casting process as carried out in a modern sand casting foundry, where technology and tradition are combined. Although it dates back...