NovaCast improves its EcoVadis sustainability score by 61%

In recognition of the remarkable sustainability improvements made during the last year, NovaCast has just been awarded a silver medal by international sustainability ratings platform EcoVadis. NovaCast operates in a traditional industry where sustainability can be difficult to achieve due to the processes involved in a foundry environment. Since taking full ownership and management control,...

Use of 3D scanning for reverse engineering and quality control

Over recent years, design engineering departments within foundries, such as NovaCast in the UK, have increasingly become the home to various digital technologies ranging from CAD systems, 3D modelling and casting simulation to 3D printing. We take a closer look at the latest addition to the digital revolution; 3D scanning technology introduced at NovaCast’s Melksham...

NovaCast further supports global initiatives to improve access to safe water and sanitation

NovaCast has been supporting global initiatives to improve access to clean water supplies since 2017, when we supported Xylem’s Watermark initiative. In 2018 we broadened our support by starting regular donations to the Planet Water Foundation, and 2020 we signed up to the WBCSD WASH Pledge for access to safe water and sanitation and hygiene...

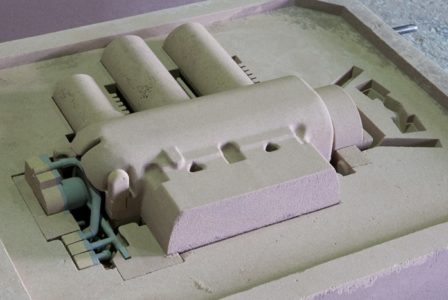

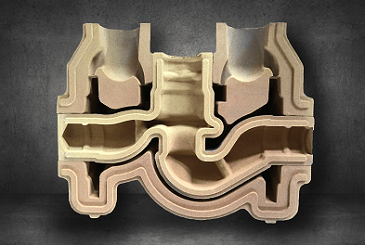

How cores extend the flexibility of sand casting

Creating cores is an art in itself and follows many of the principles that dictate the production of sand moulds. Without cores, the use of sand casting would be far more limited. In addition to the ability to introduce more complex designs, internal voids and structures, cores can deliver other benefits. Even where internal voids are not needed...

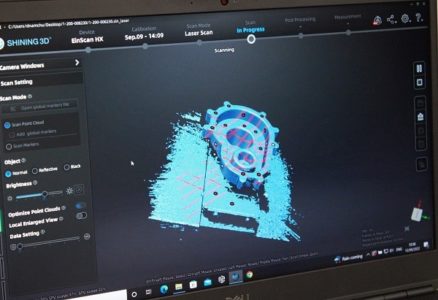

NovaCast invests in its reverse engineering capability with EinScan HX

The ability to accurately reverse engineer existing castings is essential to any modern foundry. Reverse engineering could be required for a variety of reasons ranging from replication of an old casting where original patterns have been lost to improving mechanical performance or learning from an existing design to replicate or improve it. Whatever the reason,...

NovaCast: Facing the challenges of a sustainable future

When Richard Phillips took over as owner and Managing Director of NovaCast Limited, based in Melksham, UK, he did so with a commitment that the business would move towards a sustainable future. Richard felt that as both owner and Managing Director, he had a responsibility to consider the company’s impact on the environment and to...

A global response to a global pandemic

The global pandemic has presented manufacturing and logistical issues for companies all over the world. For NovaCast, the challenge has been to maintain the supply of componentsto critical industries at a time when its own supply chains have been under pressure. Every part of our supply chain had to perform to support an Australian manufacturer...

Finishing options for sand-cast components

Sand casting has been one of the processes at the heart of the metal casting industry for thousands of years. Despite the addition of many more casting techniques and processes over the years, sand casting still accounts for 70% of all castings today. It is a highly flexible and versatile process with casting weights at...

The Investment Casting Process

The investment casting process is named after the process of ‘investing’ or surrounding the pattern with refractory material. The pattern itself is made of wax, so the process is also known as ‘lost wax casting’. The investment casting process has been used for many thousands of years to produce idols, ornaments, and Jewellery. It became...

NovaCast: A single-source solution for both ferrous and non-ferrous castings

As any Design Engineer involved in the design for cast metal components will know, the selection of the metal alloy and casting process they will specify can be a complex process. Ultimately, for the Design Engineer, the specification must take account of parameters such as weight, yield strength, toughness, ductility, weldability, elasticity, shear, and thermal...

How the metal industries can play their part in a sustainable future

It has always been widely understood that scrap metal has economic value. With ever greater focus on recycling and reducing the strain we put on our natural resources, there is also a growing appreciation of the environmental benefits metal recycling can deliver. Metals have been worked for jewellery and tools since pre-historic times and over...

Rapid Prototyping: How 3D Printing is making its presence felt in the foundry

As a long-established foundry with its roots in sand and gravity die casting, NovaCast has grown and evolved over the years to become a modern, diverse and international foundry, with customers and production partners around the world. As the business has developed, it has embraced new casting processes, such as investment casting, lost foam casting,...

Analysis and Testing of Metals: The use of Spectrometers in foundries

Over the years, technology has played an increasingly important role in metal casting foundries. NovaCast, for example, uses the latest Casting Simulation Software, 3D Modelling and 3D printing to streamline processes, raise productivity and improve quality. One such area where technology is used to great effect in foundries is the use of Spectrochemical analysis for...

The Main Alloying Elements used in Cast Stainless Steels

When considering the alloy specification for a cast Stainless Steel component, it is critical that the service environment in which the cast component will be deployed is taken into account. The chemical composition of the Stainless Steel alloy will determine its performance characteristics and suitability for each application. At NovaCast, we supply a wide variety...

NovaCast shows the way to a greener, more sustainable industry

Over the years the metal casting industry has acquired a reputation as one of the worst in terms of environmental impact, largely due to traditional production practices with high energy usage going in and highly toxic emissions coming out. Add to this the massive energy demands for the extraction and production of raw metals, such...

The Use of Fluxes in Aluminium Casting

At NovaCast, a large proportion of our castings are produced using Aluminium alloy. The formation of Aluminium Oxide and the presence of non-metallic inclusions, collectively known as dross, is an inherent part of the casting process and one that must be managed to achieve the highest quality castings. For many years, part of the foundryman’s...

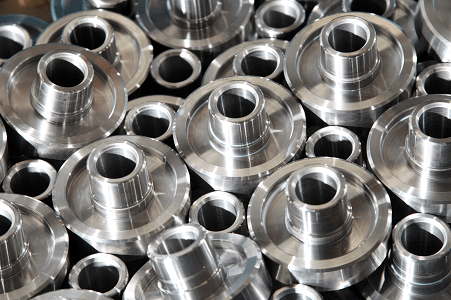

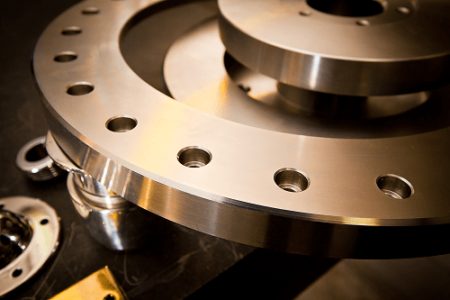

Impeller Casting Specialists

The accurate casting and balancing of impellers requires a specialist set of skills as well as a commitment to outstanding consistency and quality. For many years, NovaCast has cast and machined impellers and pump components for a wide variety of industries and applications ranging from centrifugal pumps used in the Oil & Gas, Chemical, Water...

The differences between Lost Foam Casting and Lost Wax Casting

In many respects, the process involved in these two investment casting methods is similar. In both cases, a sacrificial pattern is made. In lost wax casting, this is made from a tooled mould and in lost foam casting, it may be made from a mould or carved from a solid block of foam material. A...

The Difference Between Gravity and Pressure Die Casting

Die casting is one of the most widely used casting processes but what is the difference between Gravity Die Casting and Pressure Die Casting? Both are casting processes used by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Both forms of Die Casting employ a metal mould into...

Heat Treatment of Castings

Heat treatment of castings is primarily used to alter the physical, and sometimes chemical, properties of the cast alloy. Many of the mechanical properties of both ferrous and non-ferrous alloys are determined by their microstructure. Heat treatment Is an efficient way of manipulating the crystalline structure of the alloy to modify its mechanical behaviour in...

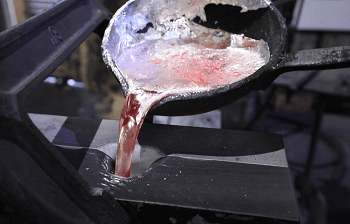

Elements of a Sand Casting Running System

The gating system includes all those elements which connect the pouring ladle to the mould. The various elements include: Pouring Basin or cup, Sprue, Sprue Base Well, Runner, Runner Extension, In-gate and Riser. An effective gating system should: Fill the mould cavity completely before the metal starts to solidify Control the speed that metal enters...

Focus on Metal Surface Treatments

NovaCast routinely uses a wide range of metal surface treatments on its cast products to enhance their mechanical, electrical or aesthetic properties. Surface treatments and finishes are often applied following surface preparation, usually in the form of fettling, linishing or shot blasting, and any final machining. Here, we focus on the surface treatments most commonly...

Aluminium Bronze in Metal Casting

The use of Aluminium Bronze in Metal Casting is widespread as it is a remarkably versatile alloy, conforming to the requirements of BS1400, and created when Aluminium is added to Copper as the primary alloying element with smaller amounts of Nickel and Iron to boost corrosion-resistance. Various grades of Aluminium Bronze are available with the...

What is Shell Mould Casting?

At NovaCast, we offer a wide range of casting process options as each have strengths and weaknesses that make them suited to certain applications and alloy choices. Shell Mould Casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable sand-based mould. However, in Shell Mould Casting,...