NovaCast Achieves B Score in Carbon Disclosure Project, Demonstrating Commitment to Sustainability

NovaCast has improved its Carbon Disclosure Project (CDP) score from a D in 2023 to a B in 2024. This achievement reflects the company’s strong commitment to reducing its environmental footprint and contributing to global sustainability efforts. The Carbon Disclosure Project is an international non-profit that drives transparency and accountability around climate change, water security,...

Metal Passivation – what it is and how it is used in metal casting

Metal Passivation – what it is and how it is used in metal casting Passivation is a process used to protect metals against corrosion by creating a protective oxide layer on the surface of the metal. The objective is to shield reactive metals from damaging chemical reactions by creating an inert, or passive barrier between...

Converting fabricated wheels to castings frees up welding capacity

Supply Plus Limited designs, manufactures and distributes a range of high quality, professional safety and fuel delivery equipment, including a mobile hose reel that has the capacity to hold up to 200m of 70mm lay flat hose. The design incorporates two wheels that were formally fabricated in-house. Due to the success of the hose reel...

The rise and rise of aluminium as a casting material

Aluminium is one of the most important raw materials used in metal casting due, in part, to its combination of versatility, relatively low weight, and high strength. It is used in castings across a wide range of industries from aerospace to automotive and electronics to renewable energy. At NovaCast aluminium is one of the primary...

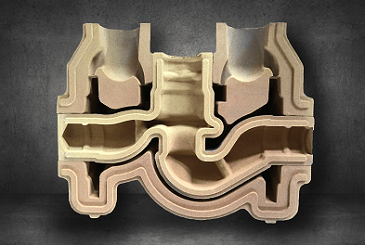

Casting Process Comparison: Sand Casting vs Shell Mould Casting

In this article we consider the differences and similarities between two closely related casting processes. Both use sand moulds to produce castings but the differences in the processes make them suited to quite different applications. Sand casting is one of the oldest casting processes dating back at least 5000 years. The simplicity and versatility of...

New Casting Process Data Sheets

Following the recent re-launch of our website, we have continued to add new content and I wanted to point you in the direction of our data sheets. We now have over 30 on the site covering the technical specifications of all the main alloys that we cast. We have also recently added data sheets for...

Metal shrinkage in castings and why it matters

Within this article, we take a look at one of the issues within metal casting that is critical to get right but challenging to understand, even for those within the industry...

NovaCast’s stockholding capability protects customers from Red Sea shipping delays

NovaCast’s customer base is a healthy mix of those ordering from our UK foundry, and those that want to take advantage of the more competitive rates and capacity of our partner foundries in the Far East and India. Clearly, for castings imported from these international locations, the current disruption in the Red Sea could have...

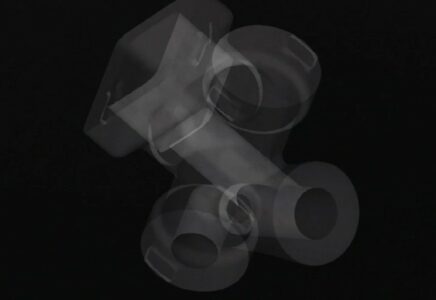

The Differences Between Non-destructive and Destructive Testing of Metal Castings

In a perfect world, every casting would be free of defects and perform exactly and reliably to design specifications. The reality, however, is that casting metal is a process subject to a multitude of factors that affect the way that an alloy reacts throughout the process. The inevitable result is that defects are an inherent...

Why quantifying progress is essential for a sustainable future

During recent years there has been an ever-growing awareness of the impact that our activities have on the world we live in. Whatever your perspective on the causes of global warming, it is a matter of fact that most of us in the developed world cause harm to our environment through the products we consume,...

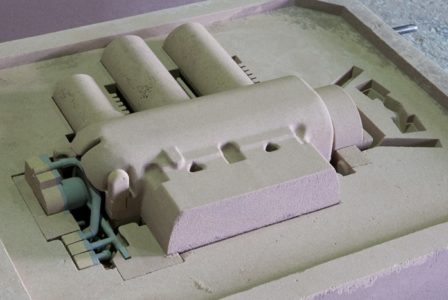

The Casting Design Development Process

In this article we run through a typical casting design process to highlight the importance of co-operation at an early stage between designer and foundry. A typical experience based on an iterative design process might be as follows. The role of the design engineers The product design engineer will design casting geometry based on the...

A successful foundry is about so much more than just casting metal

As any buyer of castings will surely understand, there are hundreds of foundries around the world who could cast their component. The complexity of the geometry or the need to use a special alloy may limit that number somewhat, and demand and supply will dictate prices and lead times, but they will still have plenty...

The Difference Between Gravity, Low and High Pressure Die Casting

Die casting is one of the most widely used casting processes but there are significant differences between Gravity Die Casting (GDC), Low Pressure Die Casting (LPDC), and High Pressure Die Casting (HPDC). Each are casting processes offered by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Getting metal...

The Leaders Council forum: Workforce Of The Future

On the 4th April 2023, a small group of business leaders, including Richard Phillips, MD at NovaCast, met at the Caledonian Club in London. The forum was convened by The Leaders Council to discuss how the workforce has changed over the past few years and the resultant opportunities and challenges. There was a specific emphasis...

Choosing the right metal casting process

Selecting the right casting process for making a metal component is an important consideration at the early stages of product design. NovaCast has produced a guide that aims to highlight the considerations, and emphasise the importance of working closely with your foundry's design engineering team.

Metal shrinkage in castings and why it matters

Within this article, we take a look at one of the issues within metal casting that is critical to get right but challenging to understand, even for those within the industry...

22 March is World Water Day

Every year since 1993, World Water Day (22 March) raises awareness and inspires action to tackle the water and sanitation crisis. It is about taking action to tackle the global water crisis of the 2.2 billion people living without access to safe water. It is a United Nations observance coordinated by UN-Water. You can find...

NovaCast improves its EcoVadis sustainability score by 61%

In recognition of the remarkable sustainability improvements made during the last year, NovaCast has just been awarded a silver medal by international sustainability ratings platform EcoVadis. NovaCast operates in a traditional industry where sustainability can be difficult to achieve due to the processes involved in a foundry environment. Since taking full ownership and management control,...

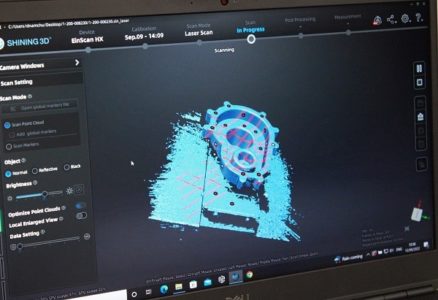

Use of 3D scanning for reverse engineering and quality control

Over recent years, design engineering departments within foundries, such as NovaCast in the UK, have increasingly become the home to various digital technologies ranging from CAD systems, 3D modelling and casting simulation to 3D printing. We take a closer look at the latest addition to the digital revolution; 3D scanning technology introduced at NovaCast’s Melksham...

NovaCast further supports global initiatives to improve access to safe water and sanitation

NovaCast has been supporting global initiatives to improve access to clean water supplies since 2017, when we supported Xylem’s Watermark initiative. In 2018 we broadened our support by starting regular donations to the Planet Water Foundation, and 2020 we signed up to the WBCSD WASH Pledge for access to safe water and sanitation and hygiene...

How cores extend the flexibility of sand casting

Creating cores is an art in itself and follows many of the principles that dictate the production of sand moulds. Without cores, the use of sand casting would be far more limited. In addition to the ability to introduce more complex designs, internal voids and structures, cores can deliver other benefits. Even where internal voids are not needed...

NovaCast invests in its reverse engineering capability with EinScan HX

The ability to accurately reverse engineer existing castings is essential to any modern foundry. Reverse engineering could be required for a variety of reasons ranging from replication of an old casting where original patterns have been lost to improving mechanical performance or learning from an existing design to replicate or improve it. Whatever the reason,...

NovaCast: Facing the challenges of a sustainable future

When Richard Phillips took over as owner and Managing Director of NovaCast Limited, based in Melksham, UK, he did so with a commitment that the business would move towards a sustainable future. Richard felt that as both owner and Managing Director, he had a responsibility to consider the company’s impact on the environment and to...

A global response to a global pandemic

The global pandemic has presented manufacturing and logistical issues for companies all over the world. For NovaCast, the challenge has been to maintain the supply of componentsto critical industries at a time when its own supply chains have been under pressure. Every part of our supply chain had to perform to support an Australian manufacturer...