As a long-established foundry with its roots in sand and gravity die casting, NovaCast has grown and evolved over the years to become a modern, diverse and international foundry, with customers and production partners around the world. As the business has developed, it has embraced new casting processes, such as investment casting, lost foam casting, pressure die casting and shell mould casting.

Production processes have also evolved as new technologies have come along and digitisation has made its presence felt. Today, NovaCast employs design engineers using the latest CAD, 3D modelling and Casting Simulation software, and 3D printing that enables fast-prototyping – both of moulds and of physical representations of the finished cast component. Here, we take a closer look at how 3D printing is employed in the foundry environment and how it is enabling rapid prototyping.

So why produce prototypes in this digital world?

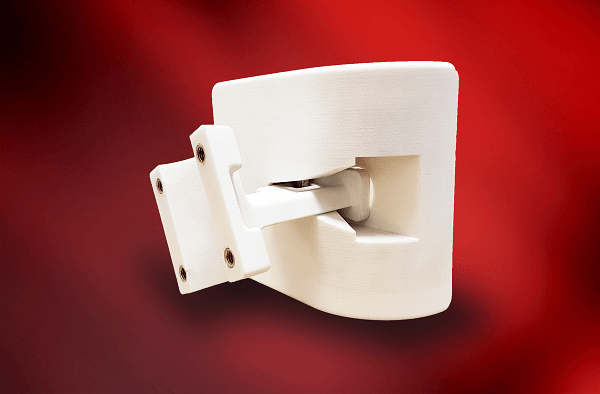

New technologies have certainly shortened production cycles and the time from concept to production is shorter now than ever before. Designs are often digital, which makes 3D modelling and on-screen images accessible, allowing designers to manipulate and view their product designs from any angle. There is no substitute, however, for having the physical prototype in your hands to refine it and improve the design.

Rapid prototyping cuts costs and time from what is inevitably an iterative process as complex patternmaking and costly tooling changes can be avoided. A full production prototype may well still be needed to check for casting defects and to obtain client approval prior to commencement of the production run but much of the trial-and-error will have been removed from the process prior to that point.

Rapid prototyping using 3D printing

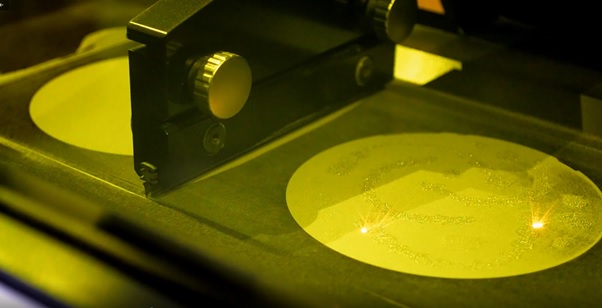

Rapid prototyping through 3D printing uses additive manufacturing technologies. Digital designs, or CAD models, are typically “sliced” by computer algorithm into many minute horizontal layers, which are then printed one at a time. At NovaCast Selective Laser Sintering (SLS) is the additive technology used which integrates seamlessly with the company’s 3D Modelling and Casting Simulation Software.

This is a technology that is still rapidly evolving and improving but it has now found a secure place, not only in the initial design phase, but also within the foundry production processes. NovaCast is now using SLS to produce loose patterns for prototyping sand-cast components, often replacing traditional patternmaking techniques. The new technologies are allowing refinement of casting geometry designs to reduce cost and weight while improving component performance.

It’s not just in sand-casting that 3D printing is reducing costs and speeding up processes. Investment casting relies on the production of a high-quality die, which is then used to produce wax patterns. These are coated in ceramic material, which forms the casting mould once the wax pattern has been melted away.

The high-quality dies are expensive to produce, and this commitment is needed early in the production process. Any errors or changes are, therefore, expensive to remedy. The use of 3D printing to create the wax patterns for prototypes eliminates the need to manufacture custom dies at this early stage. Once the prototype has been approved then a commitment can be made to more expensive tooling for the main production run.

3D printed wax patterns can also make investment casting viable for very short runs or one-off castings as the production pattern can simply be printed without the need for a die at all.

Technology makes an impact throughout the foundry

Even though it is possible to actually 3D-print metal objects, the impact of this technology on the casting industry is likely to be in the form of replacing stages in the process or speeding up the process while taking costs out, as in the case of rapid prototyping. When combined with other new technologies currently making an impact in foundries such as Casting Simulation Software and 3D modelling, 3D printing is contributing to a significant technical shift in what is one of the most traditional of industries.

For more information on the latest technologies being used in our foundries or to discuss your particular requirements please contact our technical sales team on +44 (0) 1225 707466, complete our online contact form or email sales@novacast.co.uk.