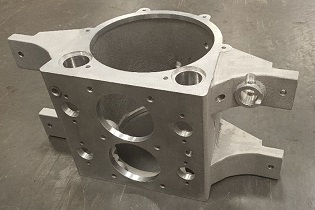

In the early 1900’s, British car manufacturers were at the forefront of motor vehicle development. The Vulcan Motor company, based in Southport, England, was one such innovator that produced cars from 1902 until the late 1920s. Today, early examples of Vulcan cars are extremely rare collectors’ items. NovaCast was approached by a specialist engineering company to help with the refurbishment of a 1906 Vulcan Phaeton which had suffered a catastrophic engine failure at some time in its past. Not only had a conrod smashed through the crankcase but the resulting overloading of components had torn the front top half of the casing in the vertical and horizontal plane. To make matters worse, the subsequent welded repair had been done so badly that the casing was severely weakened, the inlet camshaft was out of parallel, the stud holes were compromised, and an engine mounting leg was distorted.

Take a look at our case study: Vulcan Car Engine Refurbishment: Bringing a piece of British motoring heritage back to life to find out how the reverse engineering process, required to produce accurate casting geometry, was carried out by NovaCast’s design engineering team.